This is not a frivolous matter at all.

This is a deep, deep, deep subject, with lessons learned from very tragic accidents and loss of life.

Thirty-two years ago, catastrophe came to Manchester Airport when a packed passenger jet burst into flames, killing 53 passengers and two crew members. How did the disaster change air travel, and could a similar accident happen again?China Fabric Air Ducts Manufacturers

"Passengers were shouting: 'Fire! fire!' You're having a hundred thoughts. Where's your family? How were they ever going to get out?"

John Beardmore was among 131 passengers who boarded the ill-fated British Airtours flight 28M scheduled to leave for Corfu on 22 August 1985.

Hearing a loud thud as the Boeing 737 raced along the runway, the pilots at first suspected a burst tyre.

In fact, an engine failure had sparked a chain reaction, leading to a punctured fuel tank.

Take-off was abandoned and the plane was brought to a swift halt, but smoke and flames soon engulfed the rear of the aircraft, leading to panic in the cabin.

Nearly all 55 victims died from the effects of smoke inhalation as the passengers scrambled towards the front exits - one of which had become jammed - creating a bottleneck effect and stranding people at the back.

The subsequent investigation by the Air Accidents Investigation Branch led to a host of changes.

The accident was instrumental in bringing about changes to make aircraft evacuation more effective and has been described as "a defining moment in the history of civil aviation."

Acting on the recommendations of the UK's Air Accidents Investigation Branch

(AAIB), which investigated the accident, the aviation industry introduced fire-resistant seat covers, floor lighting, fire-resistant wall and ceiling panels, among many other changes.

Specifically, the investigation found that a lot of materials inside the passenger cabin produced highly toxic fumes and required airlines to look again and re-invent the wheel, so to speak.

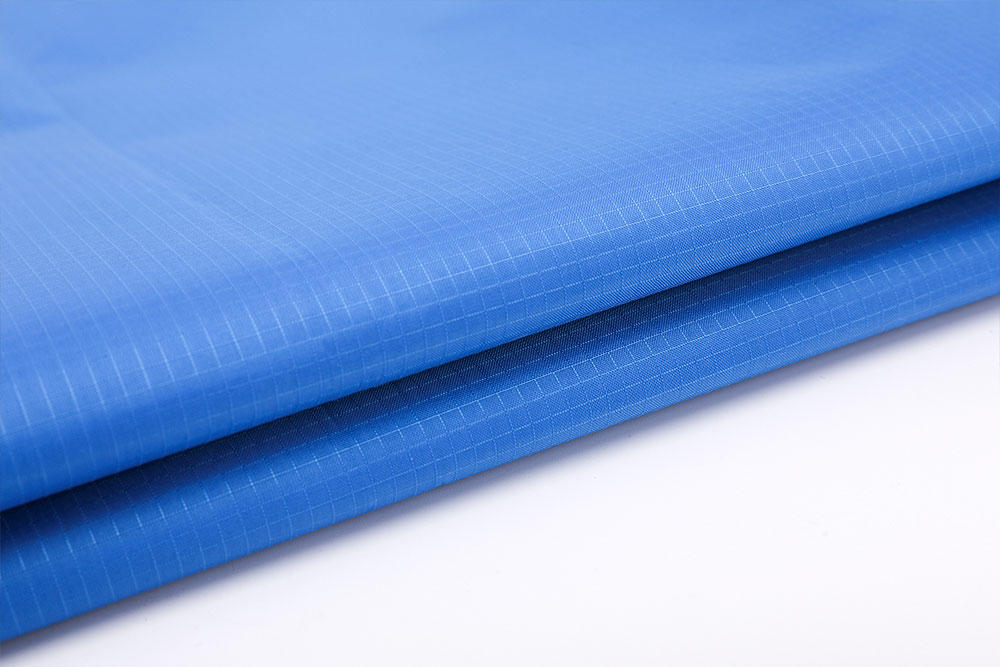

So, out went the old “Metal, plastic ,glass and fabric/”, to be replaced with new fire-resistant plastics and fabric and cushions and carpets.

The interior of an aircraft is considered to be everything that is contained inside the pressure shell, that is, the pressurized part of the aircraft fuselage.

The regulatory requirements of Federal Aviation Requirements (FAR), Part 25, that apply to interiors fall in FAR 25.853, Compartment Interiors, and FAR 25.855, Cargo or Baggage Compartments.

Although FAR 25.853 has the introductory terms ''For each compartment occupied by the crew or passengers, the following applies,'' items that are not strictly in the occupied compartment (i.e., are outside the cabin liners and not visible to either crew or passengers), such as "electrical conduit, thermal and acoustical insulation and insulation covering, air ducting," are specifically cited and the regulatory requirements are also applied to them.

The safety criteria include the FAA regulatory mandates, which address only safety and are largely quantitative. However, there are other, non-regulatory requirements such as passenger comfort level that are difficult to quantify, which complicates the task of the designers. Aircraft interior design is further complicated by the fact that many of these needs compete with each other and thus trade-offs are necessary.

Once the design of a part has been established by design engineering organizations, and once drawings describing the design and manufacture are released to the manufacturing organizations, many business processes are activated to car out acquisition of materials (inventory), tools, facilities, and manpower. If a subsequent change is made to the design, all the manufacturing planning is also subject to change, which can be time consuming and costly and creates the potential for a substantial economic penalty. There is, therefore, a strong priority assigned to designing parts "right the first time."

The current state of the art for materials used to make parts that satisfy the design criteria and other requirements fall into several main categories or families. Materials categories that could be used to fabricate more fire-resistant interiors would be subject to the same selection and use criteria.

Currently, most of the vertical and ceiling surfaces of aircraft are comprised of sandwich panels fabricated from face sheets of phenolic resin and fiberglass or carbon fiber reinforcement, and a polyaramid (Nomex) core. These panels are covered with highly formable decorative thermoplastic films that are printed in a variety of complex patterns and colors and are embossed in a wide selection of textures and gloss levels.

Fire-resistant textiles have presented some especially difficult problems.

The major material that is used for upholstery and drapery has been fire-retarded wool, with some use also made of a fire-retarded polyester, both of which meet the fire-resistance requirements and can also be dyed in an unlimited range of colors. Tapestries are held to more stringent flammability requirements than upholstery and drapery. It has been difficult to formulate a fire-retardant scheme for wool that allows it to meet the more-stringent requirements. Therefore, tapestries currently have to be fabricated of the new synthetic materials, with a fairly limited color palette or of wool/synthetic hybrid fabrics. This restriction has, to some extent, discouraged the use of tapestries. Other decorative schemes of less aesthetic appeal are being used in place of tapestries.

FAA regulatory requirements for interior furnishings are based, in large part, on flammability. The flammability mandates for transport aircraft are listed in FAR 25.853, FAR 25.855, and FAR 25.869. For most furnishings (except cabin liners, seats, and cargo liners) these comprise Bunsen burner tests to characterize resistance to ignition and ability to sustain a flame.

In addition to ignitability requirements, cabin liners are subject to additional requirements that involve control of total heat release and heat release rate and density of smoke produced.

Seats and cargo liners must meet rather severe tests based on kerosene oil burners of the sort used in home heating furnaces. Detailed descriptions of flammability test methods for indivi

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español