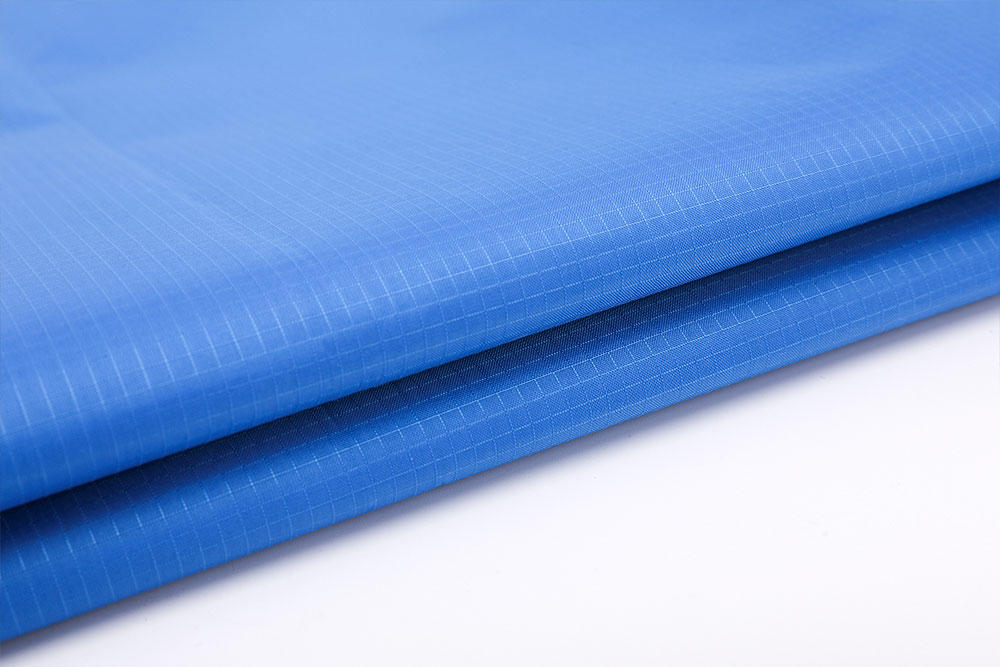

FR Combined Fabric is a blend of viscose and polyester. Both are also made into clothing on their own, but are very different to wear and care for - see below. Blending polyester with viscose gives the best of both worlds, very affordably. Polyviscose is best described as a semi-natural or semi-synthetic fibre.By blending viscose and polyester to make a new fabric quality, poly-viscose largely retains the pleasant drape and feel of standard viscose, so its touch is quite natural to handle. But the added polyester means polyviscose is much easier to care for, as it's machine washable and can be tumble-dried. It's also very robust, making it ideal for hard wearing clothes or heavy commercial settings such as public seating. Polyviscose has better wicking and breathe-sensation than most artificial fibres, but is less breathable than fully natural fibres like wool.

Poly-viscose enjoys a high lustre, which is a characteristic of both its constituent materials. And that it can be heat-set is an advantage for products like kilts or pleated ladies skirts which benefit from a permanent crease.There are three main types of customer who choose polyviscose. The first appreciates its hard-wearing and washable qualities as well as its cost-effectiveness, using the fabric in upholstery, garments or soft furnishings that are liable to wear and tear or need regular washing, such as heavy duty seating, uniforms, children's clothes, or tablecloths.Another group are those who suffer from an allergy to wool. These customers select polyviscose as a wool-substitute, thanks to its anti-allergenic or hypoallergenic properties. In fact a good polyviscose can be hard to distinguish at first sight from pure new wool when made into a skirt or kilt. So in many ways poly-viscose is an ideal alternative to wool.A third reason is that as a semi-natural product with no animal source.

So polyviscose is preferred to wool by vegans and some vegetarians.Viscose, known in the US as Rayon, is a man-made natural plant-based cellulose fibre, regenerated from dissolved wood pulp or bamboo. Viscose was first produced in France in 1883 and in commercial volumes from 1910, originally known as artificial silk although chemically it more resembles cotton. Tremendously versatile and quite cheap to produce, it has found a myriad of applications and is now the world's most produced man-made fibre. Smooth, soft, light, and comfortable, viscose drapes well, making it a favourite for swooping summer dresses, soft skirts, blouses, and synthetic velvet. Viscose resists static, and is breathable, not trapping body heat or perspiration. However, on its own viscose is not very strong, especially as it absorbs and holds water easily, losing fully half its strength when wet, making it liable to mildew if damp.

Viscose can also degrade when exposed to sunlight, and is susceptible to abrasion, shrinking, pilling, wrinkling and creasing. It should generally only be dry-cleaned.Polyester is an artificial fibre refined from oil. Pure polyester fabric, unlike viscose, is resistant to pilling, wrinkle and abrasion, and does not shrink at normal temperatures. Being 90 % crystalline, it does not easily absorb water, so dries faster, and is mildew-resistant. But this water-resistence has disadvantages too, requiring costly 'disperse dyes' to colour it, and even then being liable to sun-bleaching. This requires dying for poly-viscose to be a two-stage process. Its inability to absorb sweat makes polyester uncomfortable to wear in hot weather. But when added to viscose, these qualities mostly come into their own.Because viscose is plant-based and therefore renewable, it is widely seen as a more environmentally friendly and sustainable material than other synthetic fibres. But is this true, and what about poly-viscose? The answer is mixed. The polyester component of poly-viscose is clearly problematic, deriving from hydrocarbons, with all the implications for climate change that industry brings, plus the chemical impacts from its manufacture. In that it is similar to other artificial fibres.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español