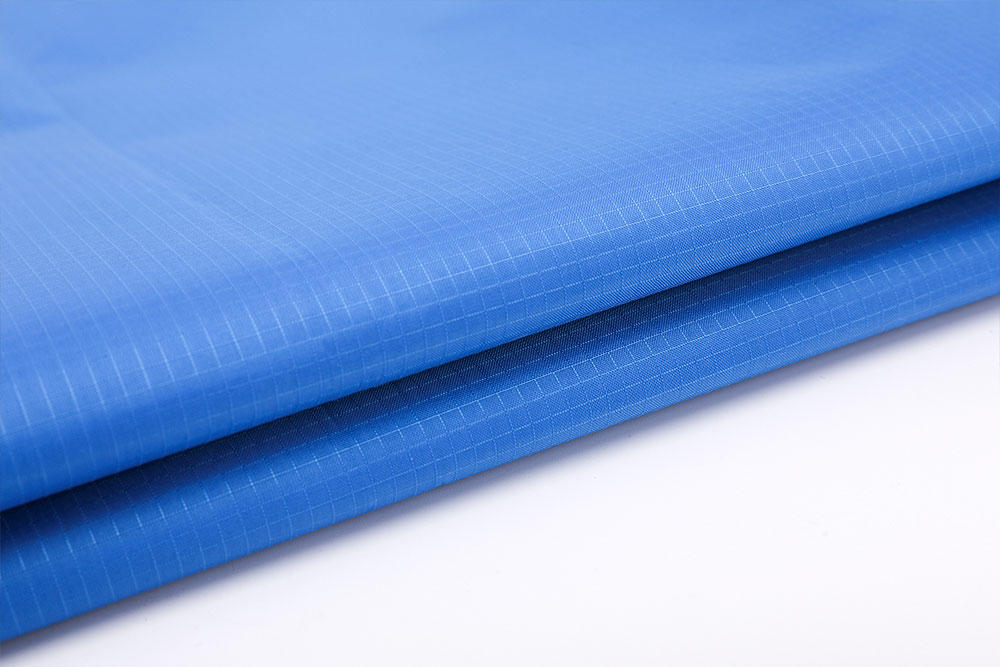

The flame retardant properties of polyester aramid sulfonamide interwoven FR Combined Fabric are shown in 1. It can be seen from 1 that the flame retardant properties of polyester sulfonamide interwoven fabrics increase with the increase of aramid fiber content. When the aramid fiber content is 0, the flame retardant performance of the fabric is when the aramid fiber content is 16, the LOI value is 25; when the aramid fiber content is 14, the LOI value is 25.8. ; When the aramid content is 12, the LOI value is 27. This is because the main chain of aramid fiber contains a large number of benzene rings, which can be condensed into aromatic carbon during combustion, resulting in less gaseous combustible products; and the formed carbon layer can cover the burning polymer The tensile properties of polyester aramid sulfonamide interwoven fabrics are as good as flame suffocation. The mechanical properties of polyester aramid sulfonamide interwoven fabrics are as follows. It can be seen that with the increase of sulfonamide content, the tensile breaking strength of the cross fabric in the warp and weft directions shows a trend of first decline and then rise.

When the aramid fiber content is 0, the warp breaking strength is 968N and the weft direction is 942N; when the aramid fiber content is 16, the warp breaking strength is 910N and the weft direction is 810N; when the aramid fiber content is 14 When the warp breaking strength is 880N, the weft direction is 746N; when the aramid content is 12, the warp breaking strength is 918N, and the weft direction is 779N. This is because the linear density of flame-retardant polyester and aramid used in this test are different, and the linear density of polyester is greater than that of aramid yarn. (1) When flame-retardant polyester is used as the warp yarn and the polyester aramid sulfone fiber blended fiber is used as the weft yarn, the warp and weft of the fabric are uneven, which directly causes the warp and weft strength of the fabric to decrease with the increase of the aramid content; (2) When flame-retardant polyester is used as the warp yarn and aramid as the weft yarn, the warp and weft surfaces of the fabric are flat, so the warp and weft strength of the fabric will increase to a certain extent. Synthesizing the aramid content on the flame retardant and mechanical properties of polyester aramid sulfone interwoven fabrics, it is found that the best ratio of polyester to aramid is 1:1, that is, when flame retardant polyester is used as warp yarn and aramid is used as weft yarn , Polyester aramid sulfone fiber interwoven fabric has good flame retardant and mechanical properties; at the same time, the interwoven fabric has a smooth appearance and a compact structure, which is convenient for subsequent processing.

The influence of the amount of glue on the flame-retardant properties of interwoven fabrics In order to further improve the flame-retardant properties of polyester aramid sulfone fiber interwoven fabrics, this topic uses non-ionic water-based polyurethane emulsion as the carrier, ammonium polyphosphate, melamine, magnesium hydroxide, thickeners, etc. As an auxiliary agent, it is compounded into a flame-retardant coating adhesive, and the polyester aramid sulfonamide interwoven fabric with the above-mentioned optimal ratio is coated and finished to further improve the flame-retardant performance of the fabric. The influence of the amount of glue on the flame retardant properties of polyester sulfonamide interwoven fabric. It can be seen that the flame retardant properties of polyester aramid sulfone fiber interlaced fabrics increase with the increase of the amount of glue. When the glue amount is 120gm2, the flame retardant LOI value of the fabric is 27.6; when the glue amount is 140gm2, the LOI value is 28.3; when the glue amount is 160gm2, the LOI value is 29.0; When the glue amount is 180gm2, the LOI value is when the glue amount is 200gm2, the LOI value is 29.5. This is because intumescent flame retardant systems such as ammonium polyphosphate and melamine have a better flame retardant effect on polyester aramid sulfone interwoven fabrics.

The effect of the amount of glue on the flame retardant properties of polyester sulfonamide interwoven fabric the effect of the amount of glue on the mechanical properties of the fabric.The effect of the amount of glue on the tensile properties of the interwoven fabric The amount of glue on the tensile properties of the interwoven fabric The influence of tensile properties is shown in.It can be seen that the warp breaking strength of polyester aramid sulfone fiber interlaced fabrics decreases rapidly with the increase of the amount of glue. When the glue amount is 120gm2, the fabric warp breaking strength is 820N; when the glue amount is 140gm2, the breaking strength is 758N; when the glue amount is 160gm2, the breaking strength is 712N; when the glue amount is 180gm2, The breaking strength is when the amount of glue is 200gm2, the breaking strength is 650N. Synthesizing the amount of glue on the flame retardant and mechanical properties of polyester sulfonamide interwoven fabrics, it is found that when the amount of glue is 160gm2, the flame retardant and mechanical properties of the interwoven fabric are more appropriate. At this time, the flame retardant LOI value of the interwoven fabric is 29.0, the LOI value before coating is 27, an increase of 7.4%; the tensile breaking strength of the interwoven fabric is 712N, and the breaking strength before coating is 918N. A decrease of 2.24%. Analysis of the burning characteristics of the cross fabric before and after coating finishing 5: Scanning electron microscopy photos of the burned residue of the cross fabric without flame-retardant coating finishing and 160gm2 .

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español