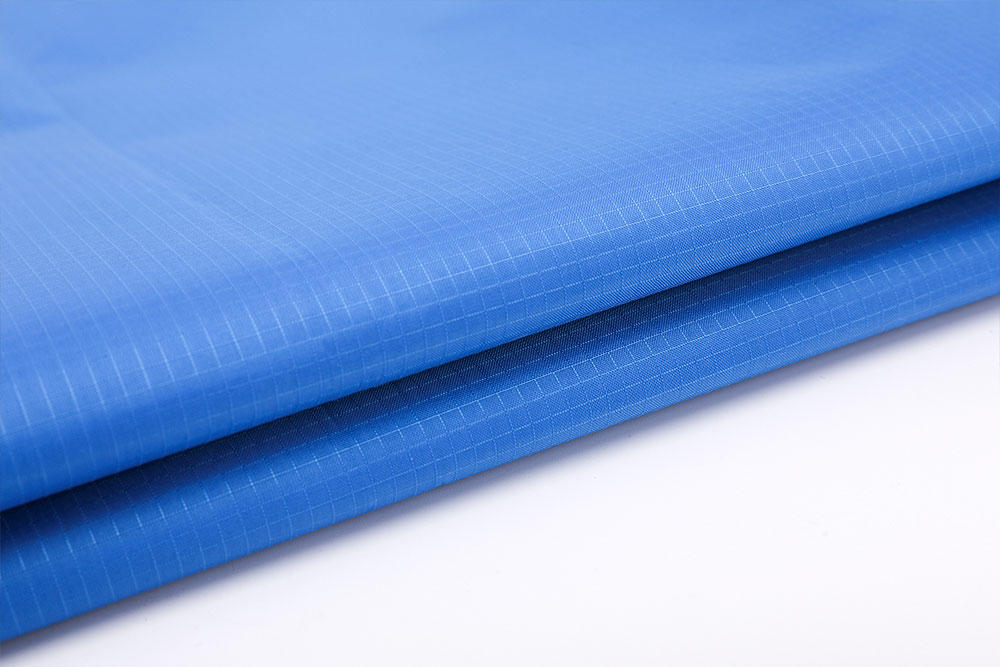

Fabric selection of a specific tent application depends on the performance requirements imposed by the end use and/or the desired aesthetic characteristics of the end user, with consideration of cost.

To achieve a practical level of waterproofness even the most tightly woven synthetic fabrics must be coated or laminated with a continuous waterproof film. In the coating process, the liquid coating substance is scraped by the fabric. The most common fabric coating polymers are polyurethane (PU), polyvinylchloride (PVC), and acrylic (polyacrylonitrile PAN). These are highly UV resistant but insufficiently flexible, particularly at low temperatures. PVC is an excellent barrier to water vapor but it is heavy. It is also particularly inflexible at low temperatures and its production and disposal are extremely harmful for the environment. Thus, polyurethane (PU) is the right coating of choice for nearly all backpacking tent fabrics. It has good resistance to wet-flexing and cold-cracking, is relatively light-weight. For a PU coating to have reasonable durability in prolonged tropical humidity or environmental dampness it must have good resistance to hydrolysis. Properly specified, well-cared-for, highquality PU coatings can last many years.

The other increasingly common waterproof fabric finishes is silicone elastomer. It may be applied to both faces of the fabric, or just on one face (which becomes the outside). Silicone rubber is widely used in various industries as fluid seals. It is highly waterrepellent, elastic, UV and temperature stable. At first glance it is the perfect coating except it is slow to completely cure so production time and cost are high. It also has poor fire-retardant properties and there are no thermo-plastic (hot-melt) or contact adhesives that stick to it. However, a serious disadvantage of fabrics that is coated with both sides of silicone elastomer is that accidental damage cannot be repaired with adhesive tapes.

The fabrics for tents are also graded in relation to the weather conditions. Three levels are defined:

Level 1

Tents designed for infrequent and short-term use. Although it is rain resistant, they are expected to be used mainly in fair weather such as summer camping.

Level 2

Tents designed for use in mainly moderate weather conditions such as reasonably wet and windy weather conditions.

Level 3

Tents designed for use in all weather conditions such as mountaineering, expeditions, snow-loading or extended residential use.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español