In the world of commercial interior design, especially in hospitality, materials matter more than ever. It's not just about aesthetics—durability, safety, and performance all play critical roles. This is where the innovative use of cationic yarn technology in IFR linen-like curtain fabric stands out. While it may sound technical at first glance, the concept is surprisingly straightforward and offers clear, measurable benefits for hotels and commercial spaces that demand more from their textiles.

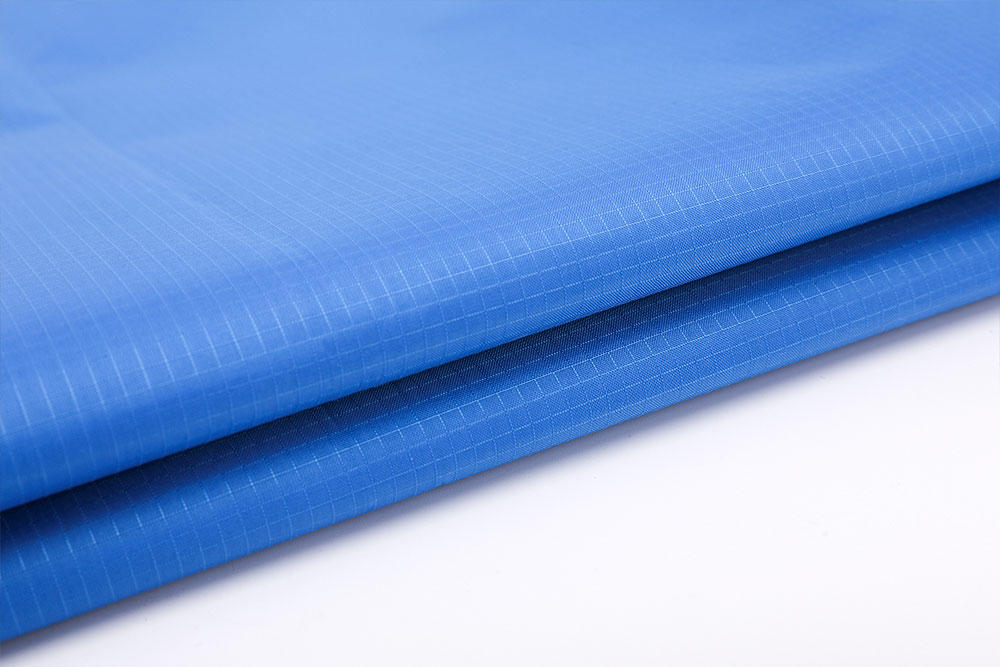

Cationic yarns are a type of modified polyester fiber that are engineered to absorb different dyes than standard polyester. This allows for deep, rich dual-tone colors with a refined texture, something that's harder to achieve with traditional fabrics. But the real advantage goes beyond color: when used in IFR linen-like curtain fabric, cationic yarns bring exceptional dimensional stability, meaning the curtains retain their shape and drape even after long-term use and frequent cleaning cycles—a must in hotel environments.

From a manufacturing perspective, using cationic yarns allows for greater consistency in dyeing, minimizing color variation and ensuring visual uniformity across large-scale installations. This is a huge advantage in the hospitality sector, where maintaining a consistent brand image through interior design is key. It also means that replacements or extensions to existing installations can be color-matched more easily, something many property managers greatly appreciate. When paired with IFR linen-like curtain fabric, the result is a curtain that not only looks upscale but also performs reliably.

One of the more practical benefits of cationic yarn is its resistance to fading. Since these yarns bind with disperse and cationic dyes at different temperatures, the final curtain fabric becomes more resistant to UV exposure—a frequent challenge for large window installations in sunny regions. This UV resistance helps maintain the fabric’s visual appeal over time, reducing the need for premature replacements and contributing to long-term cost efficiency for hospitality buyers.

In the case of our own curtain collections, the use of air compression deformation yarns along with cationic polyester offers a balance of softness, volume, and structure. This fusion creates that signature linen look while avoiding the drawbacks of natural linen, such as wrinkling and limited wash durability. Our IFR linen-like curtain fabric doesn't just imitate the elegance of linen—it outperforms it in real-world settings where maintenance and longevity are key considerations.

Importantly, the integration of inherently flame retardant (IFR) polyester with cationic yarn doesn't compromise safety for style. These curtains meet strict fire safety standards without relying on post-treatment chemicals, which can wash out over time. For architects and designers working on hospitality projects, this offers peace of mind, knowing the chosen fabric supports both regulatory compliance and design goals.

When you combine the visual depth of cationic dyeing with the performance features of IFR linen-like curtain fabric, you get a product that’s engineered for excellence. It’s not just about having curtains that look good—it’s about providing a reliable, elegant solution that enhances guest experiences and meets the demands of commercial environments. For manufacturers like us, it's rewarding to offer a product line that delivers on every front: style, performance, and value.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español