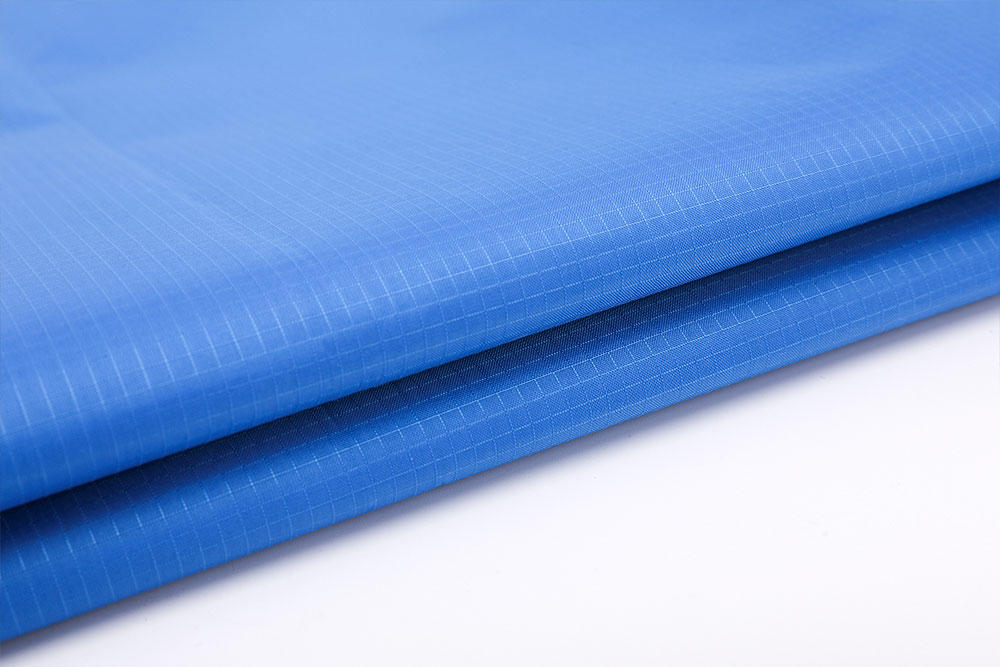

The key point of the flame retardant work clothes is the choice of fabric. So how to test the safety performance of flame retardant clothing in a simple method in the diversified market of functional clothing today? For consumers, the test conditions in a formal environment are not allowed. Here are some daily tips, which can also make a good judgment on the flame retardant performance.

1. Match Test Method

The fabric selected as much as possible during the experiment must be more than 2.5cm×30cm, this effect is the best. Just use the match we use every day to ignite it (be sure to point the flame at the center of the fabric), and you can observe the effect after the match is burned. Under normal circumstances, the fabric burns out in 5S after the match is extinguished, then the flame-retardant work clothes made of the fabric will be set as qualified. Between 5S and 15 seconds is regarded as normal. If it is above 15S, or the burning area of ??the cloth reaches half, then this product is set as unqualified.

2. Lighter test method

According to the actual situation, select the appropriate fabric to directly ignite with a lighter, time control to shut it down in 5S, wait for the flame to extinguish naturally to see its effect. If the flame spreads faster, the larger the burning area, it means that the product is not qualified, otherwise it is qualified

The daily tips are introduced here for everyone, of course, the real detection method is not the case. Generally, the flame retardant performance of the fabric is mainly judged by three major indicators: continuous burning time, smoldering time, and damage length;

The continuous burning time refers to the continuous burning time of the fabric after it leaves the fire source under the specified experimental conditions.

The smoldering time is the continuous flameless burning time of the fabric after the flame burning ends.

The damaged length refers to the length of the carbonized fabric after the combustion is completely extinguished, commonly known as carbon length.

Usually the above results require meticulous experimental equipment for measurement and statistics. The specific method is: fix the flame retardant fabric of a specific size vertically in the combustion test box, set the burning time to 12 seconds, and remove the fire source after the time is over, press The regulations of the equipment indicate the measurement of the length of damage, the time of continuous burning and smoldering, and the length of carbonization. The shorter the time, the lower the damage, the better the effect, and vice versa.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español