We all know that textile fabrics are flammable, and some special types of work clothes need to achieve flame retardant effects, such as fire service clothes, welding clothes, etc.

So how does the flame retardant fabric achieve the "flame retardant" effect?

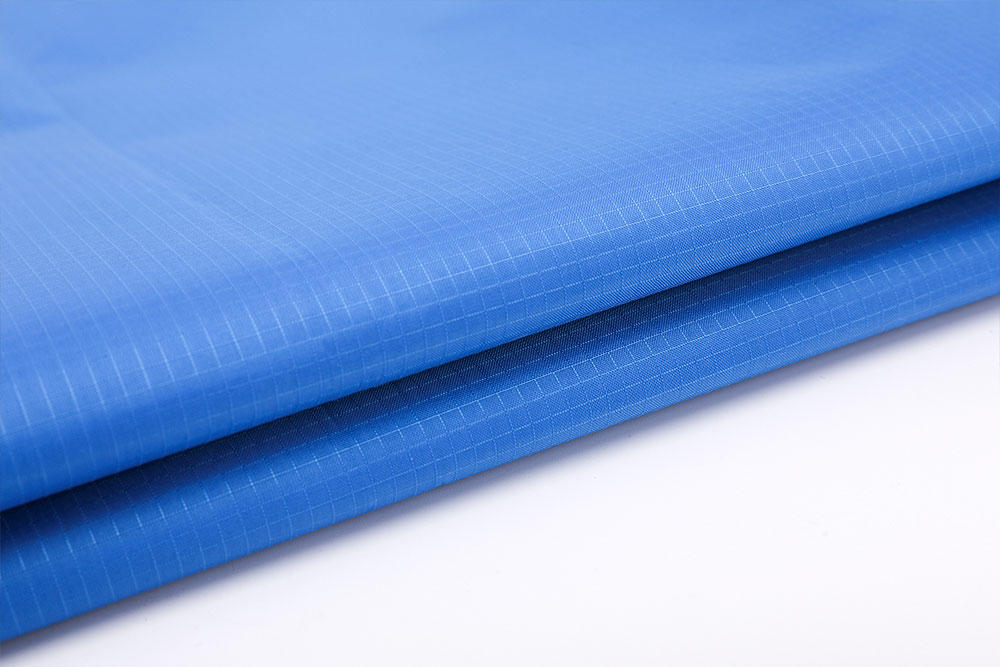

Flame-retardant fabric refers to a fabric that can be automatically extinguished within 2 s of leaving an open flame even if it is ignited by an open flame. It will ignite in the event of fire and will ignite from the fire, blocking the combustion and preventing secondary injury. Flame retardant fabrics can be divided into finishing flame retardant fabrics and fiber flame retardant fabrics.

Flame-retardant fabrics can be divided into 4 categories from the number of washing resistance: permanent flame-retardant fabrics, wash-resistant (more than 50 times) flame-retardant fabrics, semi-wash-resistant flame-retardant fabrics, disposable flame-retardant fabrics.

The finishing flame retardant fabric is produced by coating and auxiliary treatment during dyeing and finishing, and is generally used to produce things that are not washed frequently.

Fiber flame retardant fabric has permanent flame retardancy and good thermal stability. For example, acrylonitrile fiber is a modified acrylic fiber, which is a copolymer of acrylonitrile monomer and a vinyl compound containing flame retardant elements. It has a wool-like feel and high flame retardancy, and has acid resistance and chemical resistance.

Because the cost of fiber flame retardant is relatively high, the domestic flame retardant fabrics currently use more finishing methods.

Flame retardant principle

The basic principles of fabric flame retardant include surface covering flame retardant, endothermic flame retardant, condensed phase flame retardant, gas phase flame retardant and melt drop effect.

1. Surface covered with flame retardant

Some materials that melt when heated and form a protective film on the surface of the fiber after cooling, or generate non-combustible gas when heated to isolate the air from the surface of the fiber, hinder the supply of oxygen, and then achieve a flame retardant effect.

2. Endothermic flame retardant

Through the endothermic reaction of the flame retardant during combustion, it absorbs more heat and reduces the temperature of the combustion area to achieve the purpose of flame retardancy.

3. Flame retardant in condensed phase

The use of flame retardants affects the decomposition process of fibers and reduces the generation of flammable gases. This method is especially suitable for cellulose fibers.

4. Gas phase flame retardant

During the combustion process, a large number of free radicals are generated, and the addition of inhibitors can prevent the flame propagation with free radicals.

5. Droplet effect

Chemical fibers such as nylon and polyester will melt and shrink when heated, the surface area will decrease, or they will drip away from the fire source and hinder combustion.

Flame retardant applications

Due to its unique properties, flame-retardant fiber has broad application prospects in civil, military and industrial fields. It can be used not only in flame-retardant textiles for automobiles, trains and aircraft, but also in aerospace flame-retardant composite materials. , Decorative textiles in public places such as hotels, restaurants, hospitals, military, forest fire protection protective clothing and home textile products, etc.

The use of flame retardants is to make cotton and wool fibers have flame retardant properties after flame retardant finishing, while synthetic fibers such as polyester and aramid have flame retardant properties through fiber modification. Aramid flame retardant fiber products have a soft feel, good bulkiness, drape, moisture absorption and breathability and high strength, abrasion resistance, drape, good cloth finish, color fastness, and carbonization in case of fire Melt drop and other excellent characteristics, so as to meet the quality requirements of high-end flame retardant clothing and decorative fabrics.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español