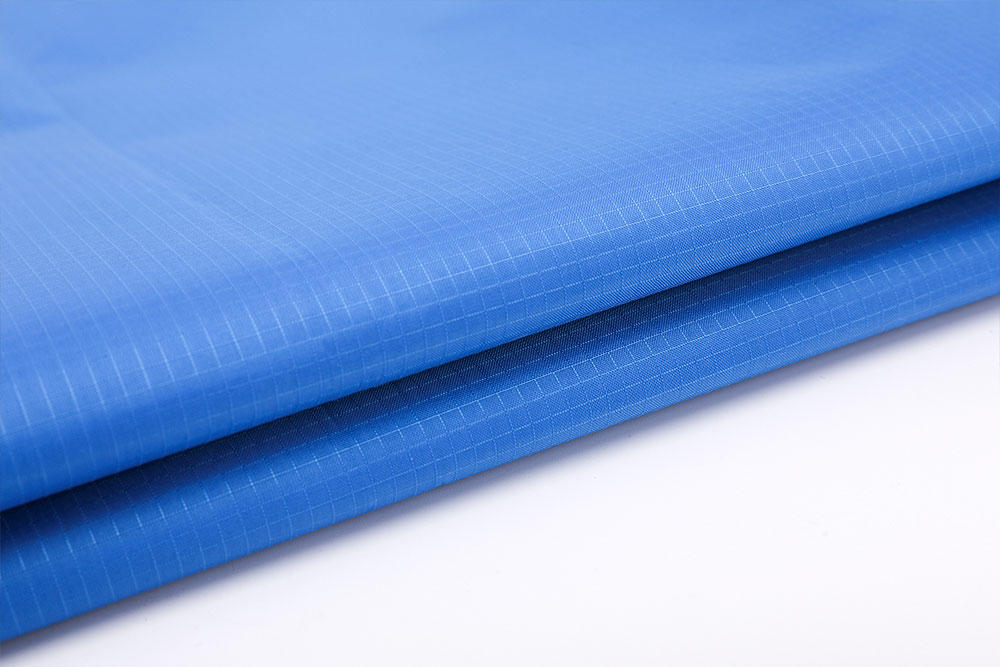

Flame retardant fiber is a new high-tech fiber material with flame retardant and anti-dropping properties. The product adopts sol-gel technology, which makes inorganic polymer flame retardant exist in nanometer state or interpenetrating network state in organic macromolecule of viscose fiber, which not only ensures excellent physical properties of the fiber, but also achieves low smoke , Non-toxic, non-odor, non-melting dripping and other characteristics.

In recent years, the fires caused by textiles all over the world have been increasing, and the losses caused by textiles are not small. Therefore, the research on flame-retardant fibers in the world has never stopped for decades.

The use of flame retardants is to make cotton, wool fibers and other fibers have flame retardant properties after flame retardant finishing, and flame retardant polyester, flame retardant aramid, flame retardant acrylic fibers and other fibers, that is, synthetic fibers, in terms of flame retardancy Is the research on the flame retardant modification of synthetic fibers.

The flame retardant modification of synthetic fiber mainly includes flame retardant modification of polypropylene fiber, flame retardant modification of polyamide fiber, flame retardant modification of polyacrylonitrile fiber and flame retardant modification of polyester fiber.

Aramid flame-retardant fiber belongs to aromatic polyamides, which is poly-m-phenylene isophthalamide fiber. Aramid flame-retardant fiber products have a soft hand, good bulkiness, drape, moisture absorption and breathability and high strength, wear resistance, drape, good cloth finish, color fastness, and carbonization in case of fire Meltdrop and other excellent characteristics, so as to meet the quality requirements of high-end flame retardant clothing and decorative fabrics.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español