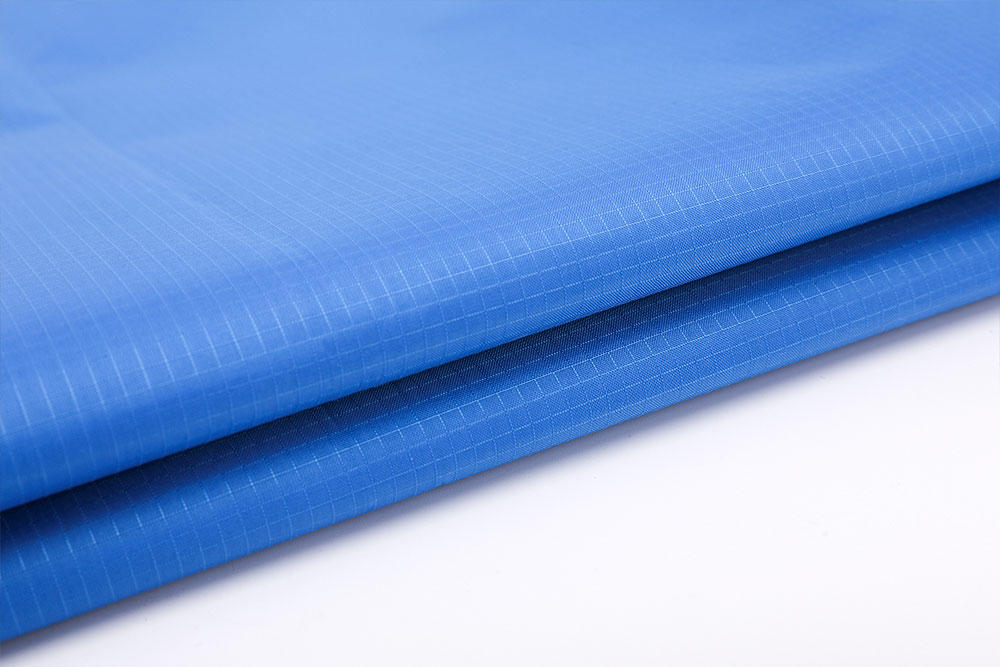

Fire retardant fabrics are used in a variety of applications like industrial work wear, uniforms for fire fighters, air force pilots, tent and parachute fabric, professional motor racing apparel etc to protect the wearer against fires, and electrical arcs etc. They are mostly used in interior materials like curtains, in hotels, hospitals and theaters. Materials like Twaron are used in fabrics to withstand high temperature in industry like fire fighting.

Materials like aluminum hydroxide are commonly used as fire retardant as it gives three way protection. It breaks down to give off water vapor, and further absorbs much heat, thereby cooling the material and the residue of alumina and forms a protective layer.

Flame retardancy of a fabric depends on the number of times; the fabric is dry cleaned, and the environmental conditions in which the fabric is used. The fire retardant properties of a finished fabric are normally tested by using addon, tensile strength, LOI-value, and vertical flame test determinations.

Flame resisting garments reduce the possibility of an incipient fire or flame from spading and becoming a conflagration. They are set up with a thermal barrier to reduce the flames spreading, to reduce after burns, and allow some time for the people to escape from the burning environment. It protects the user only for a limited time. Fire retardant fabrics include a coating of chemical that produces a non-combustible gas that prohibits the ignition and spread of fire. It also reduces the toxic smoke and fumes. Deaths during a fire accident are more likely to be caused by smoke inhalation than the actual fire itself.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español