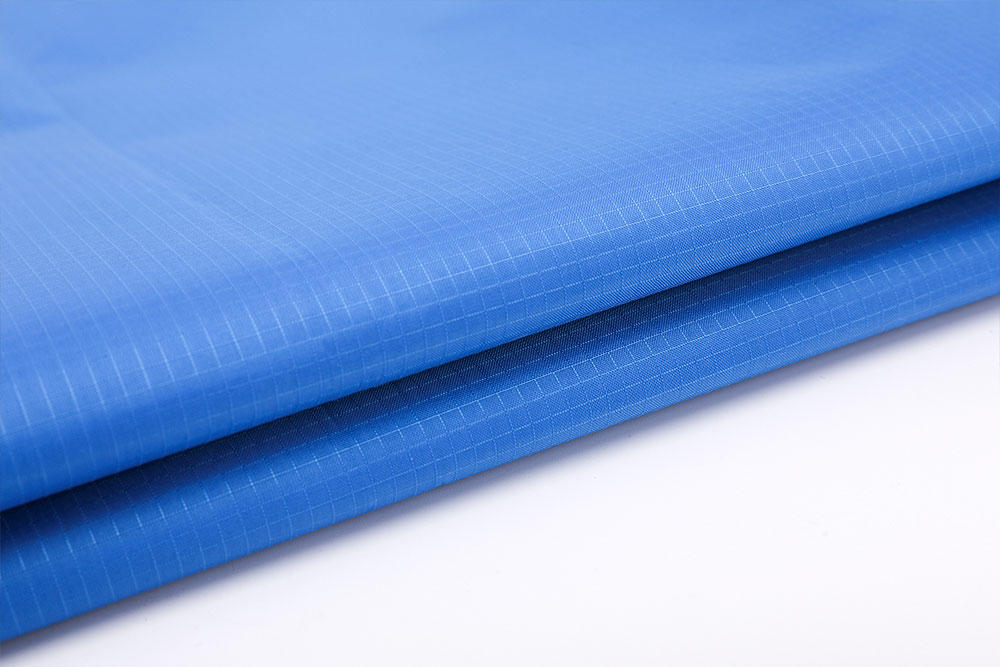

Because flame-retardant polyester has permanent flame retardancy, its application prospects will be very broad. It is understood that flame-retardant polyester has a wide range of applications. In addition to its irreplaceable role in industrial textiles, architectural FR Protecting Cover Fabric interior decoration, and vehicle interior decoration, it also plays a lot of roles in the field of protective clothing. The flame retardant protective clothing has excellent washing resistance, non-toxic, tasteless and non-irritating, safe and reliable to the human body, breathable and moisture-permeable, soft to the touch, and comfortable to wear. The English name of polyester flame retardant fabric is "PolyesterFireRetardantFabric". The flame retardancy of the fabric is often realized through the principles of gas phase flame retardant, condensed phase flame retardant and interrupted heat exchange flame retardant. It is gas phase flame retardant that inhibits the growth of the combustion reaction chain and freely exerts the function of flame retardant fabric; it retards or prevents the thermal decomposition of polymer in the solid phase and acts as a flame retardant, which is condensed phase flame retardant; part of the heat generated by the burning of polymer The flame retardant caused by taking away belongs to the flame retardant of interrupting the heat exchanger.

However, both combustion and flame retardancy are very complex processes, involving many influences and factors. It is difficult to strictly divide the flame retardant mechanism of a flame retardant system into one type. In fact, many flame retardant systems use several types of The combustion principle works. Natural fiber has health, comfort and environmental protection properties, but lacks functionality and safety. The newly developed chemical fiber simulation fiber can achieve natural fiber in terms of appearance, health and comfort, and can also achieve functionality, safety and environmental protection. Being able to look natural is better than natural. The main features of the simulated fabrics are as follows: fine denier and superfine polyester differentiated fibers-worsted wool-like fabric, ultra-high-density fabric, water and oil resistance, high-performance cleaning cloth, etc. Differentiated nylon-production of rough fabrics imitating Angola and sheep hair, and some imitating silk fabrics. Sea-island ultra-fine composite fiber-it is composed of two thermodynamically incompatible components of the sea and the island.

At present, the island component uses PET or PA, and the sea component uses COPET, PE, PA, PS and soluble PET Wait. At present, the production of sea-island superfine fibers is mainly and produces filaments, which are mainly used to make deerskin textile fabrics, while PA/COPET or PET are staple fibers which are mainly used to make synthetic leather base fabrics. Moisture-absorbing and sweat-wicking fiber modified polyester has a high specific surface area, numerous microporous grooves on the surface, a special shape in cross section, and the use of capillary effect. Air or sweat evaporates through diffusion and transmission to the outer layer of fibers, which is suitable for sportswear. This kind of moisture wicking polyester fiber has attracted the attention of the textile industry in recent years, and has continued to develop new high-end products, such as: DuPont's coolmaxAlta, Toyobo's TRIACTOR, EKSILIVE, Kurashiki Rayon PANAPACDQV, Taiwan's Zhongxing Company COOLPLUS, Far East Company TOPCOOL hero company TECHMOFIME etc.

COOPLUS series of moisture wicking polyester produced by Taiwan ZTE Textile: moisture wicking, anti-pilling, anti-ultraviolet, antibacterial and deodorant, heterogeneous fiber, moisture wicking black, two-color silk and other fibers. Use flame-retardant polyester and conductive fiber to interweave to produce anti-static flame-retardant fabric; use flame-retardant fiber and high-performance fiber to blend and interweave to produce high-performance flame-retardant fabric; use flame-retardant fiber and cotton, viscose and other fibers to blend, To improve the comfort of protective clothing and reduce secondary burns. Flame retardant polyester, flame retardant polypropylene, flame retardant viscose. Which effect is better?Flame-retardant polyester will be better if it is used to make clothing fabrics. Because polyester is stiff and not easy to wrinkle, it has high strength, good impact resistance, heat resistance, corrosion resistance, moth resistance, acid and alkali resistance, and good light resistance (second only to acrylic. It can maintain 60-70% strength after 1000 hours of exposure. , The moisture absorption is very poor, the dyeing is difficult, the fabric is easy to wash and dry, and the shape retention is good.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español