Fire prevention in public spaces has received increased attention in recent years. As a result, the Flame Retardant or Flame Resistant properties of fabric has become an integral part of the design and manufacturing decision-making process. They are manufactured with Flame Retardant chemicals either in fiber or fabric form, at the mill, or treated afterwards by a certified applicator.

Many conditions affect the flame resistance of a fabric: how the fabric is used; what other fabric or non-fabric components are added to the base fabric; environmental conditions such as sunlight, dust, humidity, etc., length of time in service, sewing, printing, painting or any other added processing steps. It’s the customer’s responsibility to verify that the completed design passes the appropriate Federal, State and Local Fire Codes. Dazian can assist you with our experience and knowledge, but cannot assume responsibility how our customers use and maintain their finished product.

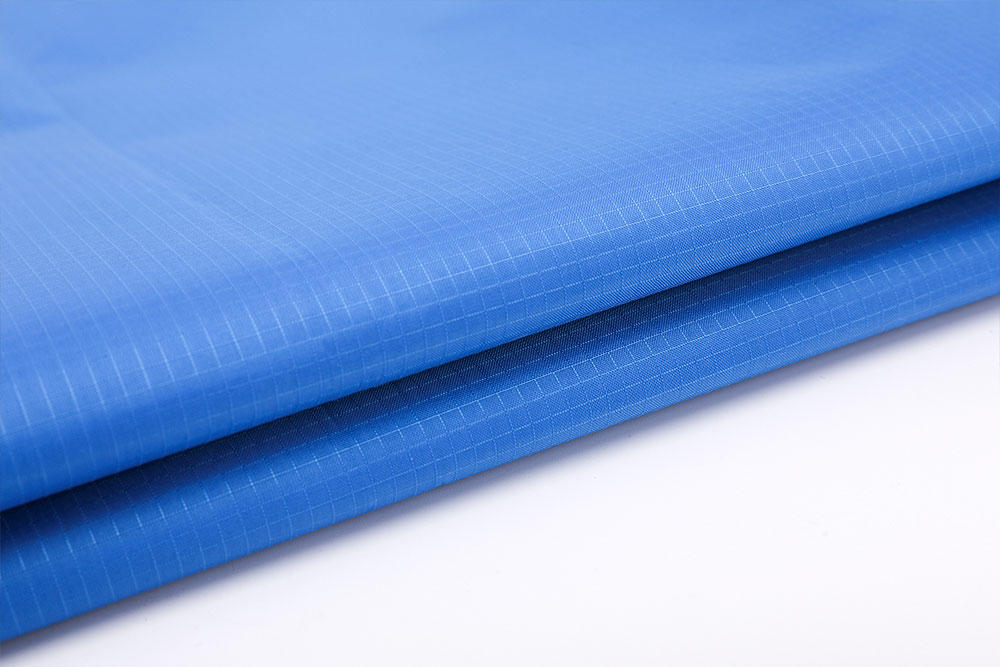

Traditionally, IFR fabrics have been defined as fabrics constructed with yarns manufactured with FR additives. This process imparts Permanent Flame Retardant properties to a fabric over its service life.

New type of FR fabric technology permanently bonds FR additives to Polyester fibers in the dyeing and finishing process of fabric formation. This process creates Permanent Flame Retardant properties to the fabric over its service life, often with superior FR performance than fabrics manufactured only with FR fibers.

99.99% FR cotton fabrics cannot stand up to high humidity, or washing. Flameproofed polyester fabrics have greater durability and longevity, but in many cases still require subsequent re-treatment.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español