Flame retardant fabrics have become an essential part of textile selection for public and commercial spaces, and IFR Chenille Curtain Fabric offers a distinctive balance between technical performance and visual warmth. As inherently flame retardant (IFR) materials become more widely specified by architects and buyers, understanding how chenille compares to other FR curtain fabrics—such as treated polyester or specialized fibers like Trevira CS—is crucial for making an informed choice.

Unlike fabrics that rely on topical chemical treatments, IFR chenille derives its flame retardant properties from its fiber composition itself. This means the flame resistance is permanent and will not degrade over time or through repeated washing. Treated polyester, by contrast, often loses effectiveness after cleaning cycles and requires reapplication to maintain safety standards. In large-scale applications such as hotel interiors or healthcare facilities, durability and compliance are not just preferences—they are operational necessities.

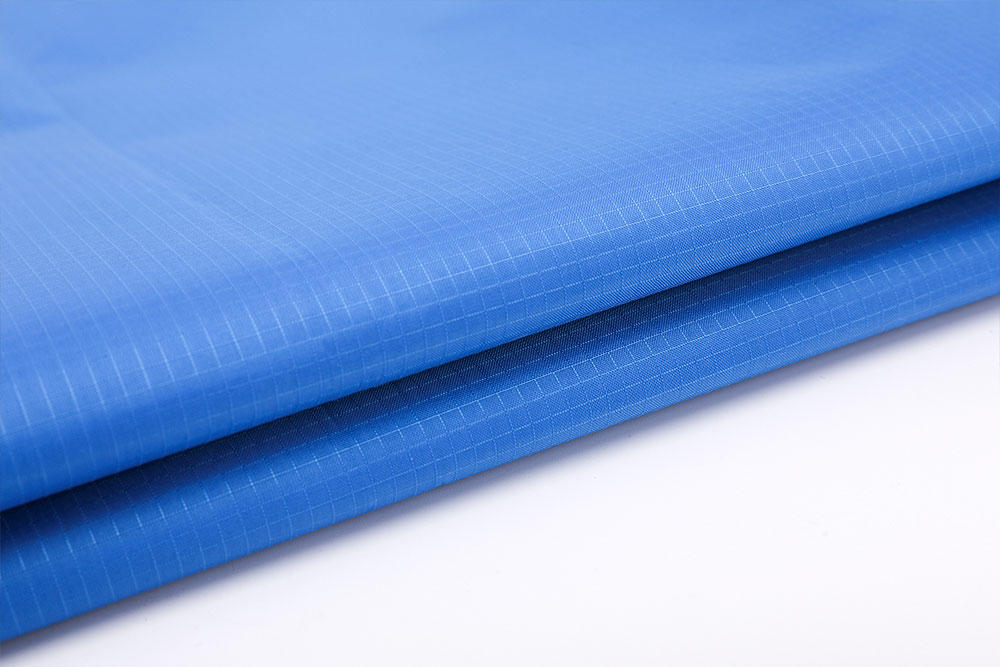

Chenille is known for its soft hand and rich surface texture, which come from the pile yarns that create a slightly raised, velvety touch. This tactile advantage is difficult to replicate with many other FR curtain materials, which tend to prioritize performance over aesthetic appeal. IFR Chenille Curtain Fabric manages to bridge that gap, offering a product that feels plush without compromising on technical function. In environments where guest comfort and ambiance matter—such as high-end hospitality projects—this balance makes a noticeable difference.

Another key differentiator is the drape behavior. IFR chenille’s woven construction provides excellent fall and fluidity, maintaining structured elegance across different window dimensions. By contrast, heavier synthetics can appear rigid or lack the softness required for seamless styling. While Trevira CS fabrics are known for their flame resistance and ease of maintenance, they often come with a tradeoff in tactile experience and require a stiffer hand to achieve certain certifications.

Shading capabilities further distinguish IFR chenille. Available in options from mid to high shading levels, it offers versatile solutions without relying on extra coatings or liners. This reduces installation complexity and helps maintain the original look of the fabric. Additionally, its innate thickness and textured surface enhance sound absorption, a feature not typically emphasized in standard flame retardant polyesters. In commercial or institutional settings that value acoustic comfort—like meeting rooms or rehabilitation centers—this can be a subtle but important benefit.

Environmental stability is also worth considering. High color fastness, UV resistance, and dust-blocking capabilities make IFR Chenille Curtain Fabric suitable for settings exposed to natural light and high human traffic. While some other FR materials match these qualities, few do so with the same depth of texture or thermal insulation. This multifunctional performance, combined with the visual softness, positions IFR chenille as a strong candidate for both functional and decorative roles.

For importers and purchasing agents evaluating materials by square meter and performance metric, chenille’s composition offers a practical and visually appealing alternative. Its permanent flame retardancy, coupled with a luxurious finish, helps reduce long-term maintenance costs while enhancing overall space design. By choosing IFR Chenille Curtain Fabric, you're not only selecting a reliable safety solution—you’re also bringing warmth, depth, and lasting value to your interiors.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español