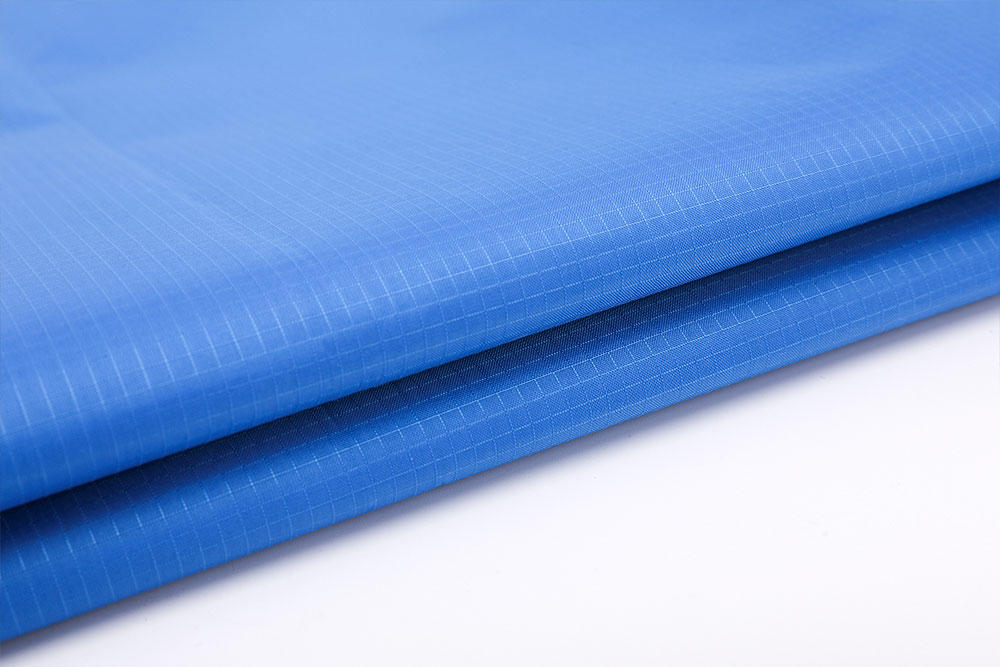

While developing a custom carrying case or custom sewn product, durability is almost always a major factor to keep in mind while sourcing fabrics. Using textiles with high durability against wear and abrasions is especially important in the medical and military fields where product failure is not an option.

A Coated Fabric is a fabric that has been treated to make them longer lasting, stronger, and more weather resistant. Rather than interweaving a strengthening fiber directly into the fabric, these fabrics are coated with a substance that makes the fabrics’ surface more impervious to damage. The most common coating is polyethylene, the most basic plastic compound, which has proven its durability through its use in the packing industry. Other coatings include rubber and plastic resins, polyvinyl chloride, acrylic, laminates, PVC, and more.

Coated Fabrics also lead to further coating customization. At it’s most basic level, most coatings make the fabric not only more durable, but water resistant (and in the case of some treatments, even completely water proof). Textile manufacturers have the ability to customize a coat for any fabric to meet a diverse array of needs, ranging from something as simple as mildew resistant to something as powerful as fire resistance. This opens up for experimentation and further customization of the durability features that your product has.

Coated fabrics can also benefit the medical field. For example, using an antimicrobial coating on a fabric can seriously reduce spread of germs. This type of fabric could be used in an EMS carrying case or a medical wearable device.

With new and more effective fabric treatments in development, Coated Fabrics are an excellent choice for projects that need increased durability and resistances to certain specified elements.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español